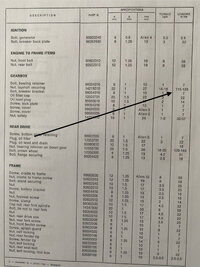

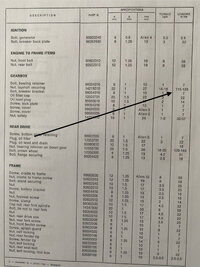

So I have a problem with my gearbox refurbishment that leads to this question. What is the Torque setting for the Lay Shaft LH retaining nut? My research and the Workshop manual says 115 to 129 ft/lbs. At 90 ft/lbs. I stripped the thread on a new nut just purchased from MG Cycle. Bad aftermarket product or is the 115-129 ft/lbs suspect?

I've been refurbishing the gearbox on my 850 T this past winter and am reassembling it now. The old lay shaft LH thread retaining nut was a bit chewed ( see pic) so I thought it would be a good idea to replace it. It was also loose on the shaft when I pulled the gear box apart. So it definitely had been opened before. So the 115 to 129 ft/lbs is correct? Should I try Harpers or somewhere else for the nut? Any suggestions?

PS I've reviewed the various posted threads pertaining to the 5 speed gear boxs and haven't come across anything specific to this question. My apologies in advance if i have missed it.

I've been refurbishing the gearbox on my 850 T this past winter and am reassembling it now. The old lay shaft LH thread retaining nut was a bit chewed ( see pic) so I thought it would be a good idea to replace it. It was also loose on the shaft when I pulled the gear box apart. So it definitely had been opened before. So the 115 to 129 ft/lbs is correct? Should I try Harpers or somewhere else for the nut? Any suggestions?

PS I've reviewed the various posted threads pertaining to the 5 speed gear boxs and haven't come across anything specific to this question. My apologies in advance if i have missed it.