G11, 6,000 miles

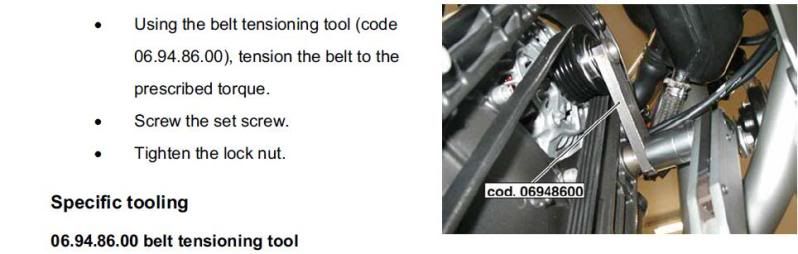

I know nobody has/uses the Moto Guzzi specified alternator belt tension tool, and the 90 degree belt twist method has been referenced here. Checked my belt tension for the first time. Yeah, with moderate tesion, I can twist it 90 degrees. With more force, I go go a little beyond 90 degrees: Adequate, or worth tightening?

The problem I have with methods like these is how hard should I be trying to deflect the belt. Can anyone compare to a simple belt deflection in the middle of the span ( a method I'm a little more used to)? I can get a little more than 1/4" of deflection.

I know nobody has/uses the Moto Guzzi specified alternator belt tension tool, and the 90 degree belt twist method has been referenced here. Checked my belt tension for the first time. Yeah, with moderate tesion, I can twist it 90 degrees. With more force, I go go a little beyond 90 degrees: Adequate, or worth tightening?

The problem I have with methods like these is how hard should I be trying to deflect the belt. Can anyone compare to a simple belt deflection in the middle of the span ( a method I'm a little more used to)? I can get a little more than 1/4" of deflection.