@scottmastrocinque I'd like your perspective on this, if you're bored. I took a minute to illustrate my analysis of the construction of this thing to explain my rationale about why the structures I removed had no bearing on the integrity of the box. Seems like you're as big (or bigger) of a nerd than I am (and being that we're already committed to the bet) I wanted to explore this a bit more since you said you had some experience here. I'm actually building some parts in Autodesk Fusion 360 and 3D printing them as well (for other projects) anyway, so I'm in this headspace right now, and figured I'd just think out loud.

See the attached illustration:

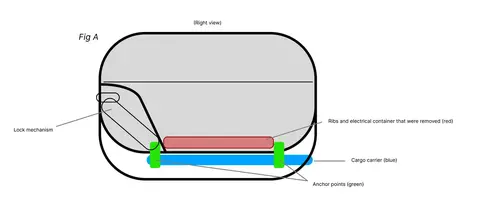

Fig A shows the structure of the box as it's attached to the bike. The important part to note is the anchor points (green) extend beyond the part of the bottom parts that I removed (red).

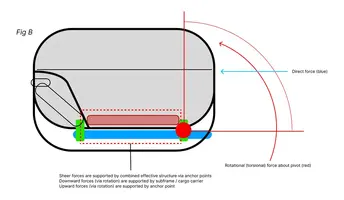

Fig B shows the direct force (blue) of a passenger leaning back on the box, and the corresponding rotational force (red). In this case, some of the force would transfer through the top structure of the box, pushing down on the structure aft of the fore pivot point, pushing down on the entire structure. Sheer forces would be entirely supported by the anchor points themselves, and even if those ribs were made of titanium, they wouldn't do anything to help stability from sheer force. Upward force is also fully supported by the anchor (pivot) point. Thus:

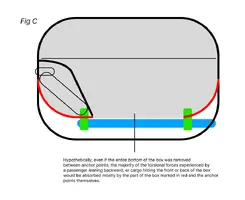

Fig C shows that even if the entire bottom of the box were removed between the anchor points, the majority of the flex imposed on the entire system would act on the red part of the box, not on the part that was removed. Effectively, the anchor points create a single system between the box and the cargo carrier. This discussion would be entirely different if one of the anchor points were, say, in the middle of the bottom of the box, where I removed the plastic.

Additionally note that the ribs and spars ran fore/aft, meaning that they didn't have any effect on lateral forces, so I'm not including that part for analysis.

Finally, this includes some assumption around the strength of the forces as well: If you applied very intense forces to the backrest here, or to the inside of the case (say loading it with 80lbs of gear and coming to an abrupt halt...), it would cause rotational force about both the fore and aft pivot points, which would potentially cause the floor of the box to bow upward, which would stress the pivot points themselves and potentially lead to failure. However, a force of that magnitude would certainly be in the realm of abuse, in which case there are many other potential points of failure in the system, so I'm not considering that to be a factor here.

Anyway, let me know if I'm overlooking something here, in theory. In practice, time will tell.

Thanks for indulging me with your brain!

See the attached illustration:

Fig A shows the structure of the box as it's attached to the bike. The important part to note is the anchor points (green) extend beyond the part of the bottom parts that I removed (red).

Fig B shows the direct force (blue) of a passenger leaning back on the box, and the corresponding rotational force (red). In this case, some of the force would transfer through the top structure of the box, pushing down on the structure aft of the fore pivot point, pushing down on the entire structure. Sheer forces would be entirely supported by the anchor points themselves, and even if those ribs were made of titanium, they wouldn't do anything to help stability from sheer force. Upward force is also fully supported by the anchor (pivot) point. Thus:

Fig C shows that even if the entire bottom of the box were removed between the anchor points, the majority of the flex imposed on the entire system would act on the red part of the box, not on the part that was removed. Effectively, the anchor points create a single system between the box and the cargo carrier. This discussion would be entirely different if one of the anchor points were, say, in the middle of the bottom of the box, where I removed the plastic.

Additionally note that the ribs and spars ran fore/aft, meaning that they didn't have any effect on lateral forces, so I'm not including that part for analysis.

Finally, this includes some assumption around the strength of the forces as well: If you applied very intense forces to the backrest here, or to the inside of the case (say loading it with 80lbs of gear and coming to an abrupt halt...), it would cause rotational force about both the fore and aft pivot points, which would potentially cause the floor of the box to bow upward, which would stress the pivot points themselves and potentially lead to failure. However, a force of that magnitude would certainly be in the realm of abuse, in which case there are many other potential points of failure in the system, so I'm not considering that to be a factor here.

Anyway, let me know if I'm overlooking something here, in theory. In practice, time will tell.

Thanks for indulging me with your brain!