Hi all,

First post on electrical charging problem with my recently acquired NTX350. Bike is in good condition and starts OK but charging warning light stays on.

I am new to this type of charging system ( my 1988 Tenere XT600 3AJ uses permanent magnets).

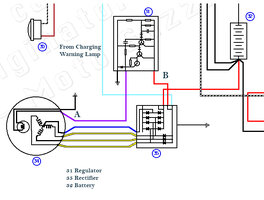

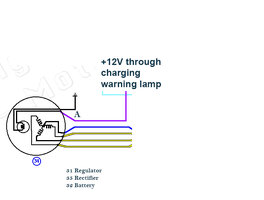

I have attached the relevant part of the circuit diagram I am using.

I have taken the following measurements:

Field Coil Resistance 3.9 ohms

Charging bulb resistance 14.3 ohms measured back to battery positive.

3 phase winding to winding 0.8 ohms (same across all phases)

Votltage at point B with ignition on and engine not running 12V

Voltage at point A with ignition on and engine not running 0.46 V

My understanding is that the circuit through the charging lamp to the regulator should initially provide sufficient current to excite the field coil to produce the magnetism to generate the 3 phase AC. As engine runs and AC increases the rectified voltage increases to a certain voltage (14 V say) the regulator stops supplying current to the field coil.

My problem is that I am getting no 3 phase output with the engine running.

The voltage at pont A could be calculated as the ratio of the resistances of the field coil and the charging warning lamp less any voltage drop across the regulator internal transistors and diodes (say 2.1V across 3 off 0.7V junction drops) so should be around (12-2.1) x (3.9/14.3+3.9)) = 2.12V

I am only seeing 0.46 V at point A

If I disconnect the wire from the regulator going to the Field coil +ve I see 5.6 V on the wire

If I connect +12V momentarily straight across the field coil, the 3 phase windings generate 3 phase power no problem with the engine running.

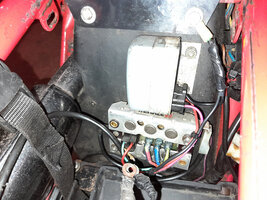

Also I am a bit surprised that one half of the rectifier diode board is at +12V and the other half is floating. The circuit diagram shows the casing as earthed, but I cannot see a terminal on the board to connect the earth to. I have attached a pic of what I believe are the connections to the diode board.

A and B - feed from warning lamp to regulator (connected together)

C,D and E - 3 phase input

F - rectifier output to battery

G - star point from stator windings.

I am a bit lost here, can someone please help.

Thanks,

Jim

First post on electrical charging problem with my recently acquired NTX350. Bike is in good condition and starts OK but charging warning light stays on.

I am new to this type of charging system ( my 1988 Tenere XT600 3AJ uses permanent magnets).

I have attached the relevant part of the circuit diagram I am using.

I have taken the following measurements:

Field Coil Resistance 3.9 ohms

Charging bulb resistance 14.3 ohms measured back to battery positive.

3 phase winding to winding 0.8 ohms (same across all phases)

Votltage at point B with ignition on and engine not running 12V

Voltage at point A with ignition on and engine not running 0.46 V

My understanding is that the circuit through the charging lamp to the regulator should initially provide sufficient current to excite the field coil to produce the magnetism to generate the 3 phase AC. As engine runs and AC increases the rectified voltage increases to a certain voltage (14 V say) the regulator stops supplying current to the field coil.

My problem is that I am getting no 3 phase output with the engine running.

The voltage at pont A could be calculated as the ratio of the resistances of the field coil and the charging warning lamp less any voltage drop across the regulator internal transistors and diodes (say 2.1V across 3 off 0.7V junction drops) so should be around (12-2.1) x (3.9/14.3+3.9)) = 2.12V

I am only seeing 0.46 V at point A

If I disconnect the wire from the regulator going to the Field coil +ve I see 5.6 V on the wire

If I connect +12V momentarily straight across the field coil, the 3 phase windings generate 3 phase power no problem with the engine running.

Also I am a bit surprised that one half of the rectifier diode board is at +12V and the other half is floating. The circuit diagram shows the casing as earthed, but I cannot see a terminal on the board to connect the earth to. I have attached a pic of what I believe are the connections to the diode board.

A and B - feed from warning lamp to regulator (connected together)

C,D and E - 3 phase input

F - rectifier output to battery

G - star point from stator windings.

I am a bit lost here, can someone please help.

Thanks,

Jim