Hi All,

I've just finished rebuilding the cylinder heads on my 1984 V65. I have upgraded to the later single-spring valve arrangement and hope to put the engine back together tomorrow. Three out of 4 valves were leaking so new valves have been lapped in, the cylinders have been deglazed and carbs, cylinders, heads and inlet elbows have all been vapor blasted so it's looking good!

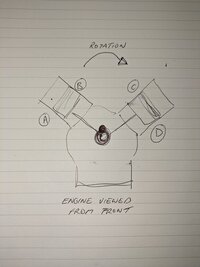

In order to properly clock the rings, I'm looking for some help. Based on my diagram, can someone advise if my assumption that cylinder surfaces B & D would be the "thrust" surfaces?

Thanks!

I've just finished rebuilding the cylinder heads on my 1984 V65. I have upgraded to the later single-spring valve arrangement and hope to put the engine back together tomorrow. Three out of 4 valves were leaking so new valves have been lapped in, the cylinders have been deglazed and carbs, cylinders, heads and inlet elbows have all been vapor blasted so it's looking good!

In order to properly clock the rings, I'm looking for some help. Based on my diagram, can someone advise if my assumption that cylinder surfaces B & D would be the "thrust" surfaces?

Thanks!