Penis Rotor

GT Godfather!

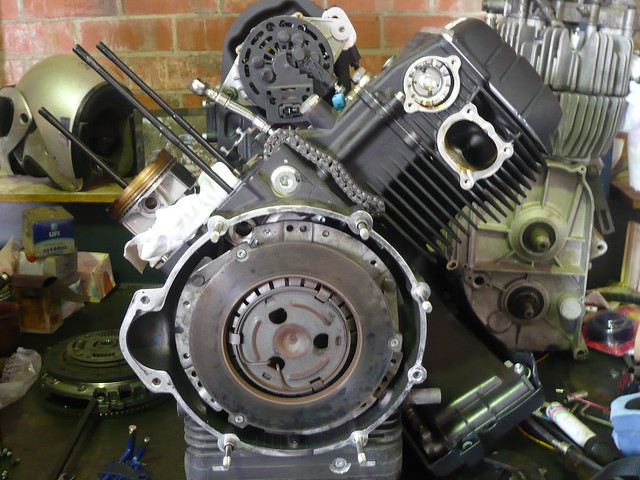

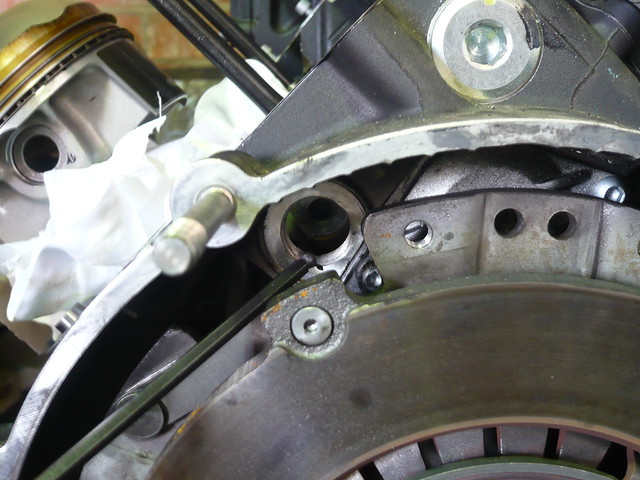

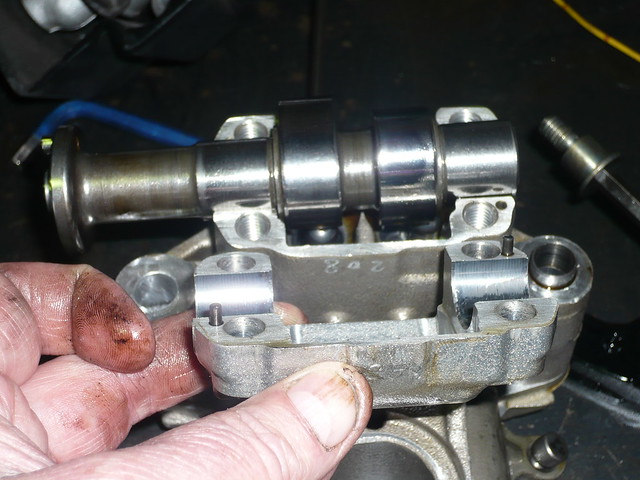

Would people like me to take and post up some pics of this 8V engine I'm workin' on? The parts won't be here until later today/tomorrow and it's all apart on the bench, (As far as it needs to be Mark! I haven't completely stripped it for shit and giggles. I can if you want? :twisted: ) so it's no big deal. If nobody's intersted I won't bother though.

Pete

Actually Mark, while the frame is sitting with it's arse in the air I'll go through and add a whole load of grease to all the bits that the factory leaves conspiculously grease free on assembley! Nothing important mind, just stuff like the swingarm bearings and shock linkages!!!! :lol: :roll:

Pete

Actually Mark, while the frame is sitting with it's arse in the air I'll go through and add a whole load of grease to all the bits that the factory leaves conspiculously grease free on assembley! Nothing important mind, just stuff like the swingarm bearings and shock linkages!!!! :lol: :roll: