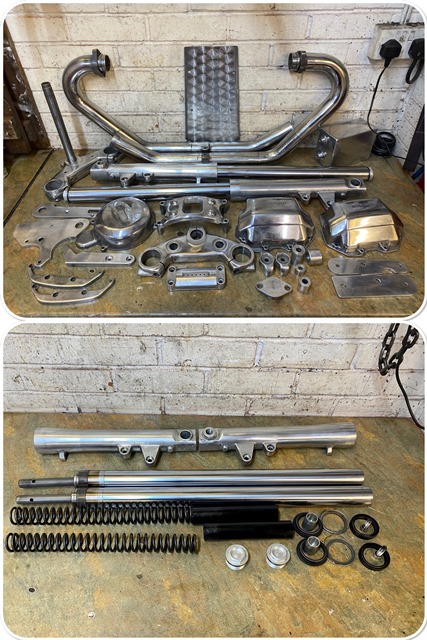

Autumn arrives… Bike rides become less frequent, and the holiday and days out season slows down, so its back in the garage! the bike is now in the stage where all the fabrication is done and it all needs taking apart and cleaning and painting. Engine removal was quite easy with the removable frame rails and it was all soon apart and the engine and gearbox on the bench. I finished off all the welding on the frame and removed all the unused lugs to get that clean look, and sent it off to the powder coaters.

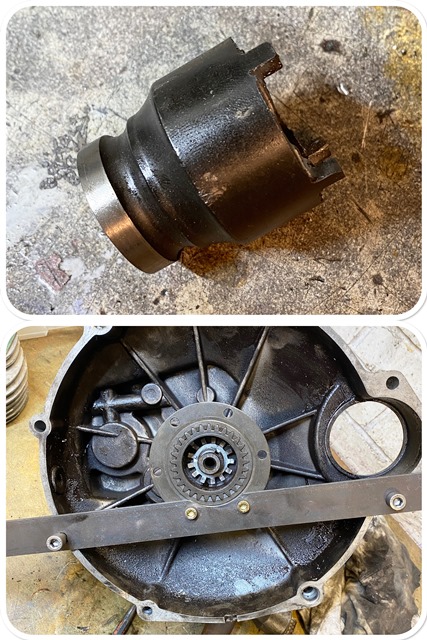

I will be doing a full engine gearbox and drive unit rebuild, mainly to vapour blast the cases. This of course means making a few special tools! First off was an extra long 32mm socket. I cut down a standard one and extended it with some thick wall tube.

next was a tool to undo the 27mm nut on the gearbox output shaft. you need to hold the shaft as well as turn the but so it needs to accommodate this. I used one of the spare Ducati wheel nut spanners I had laser cut years ago and bored it to shape on my new milling machine. Picture of that to follow!

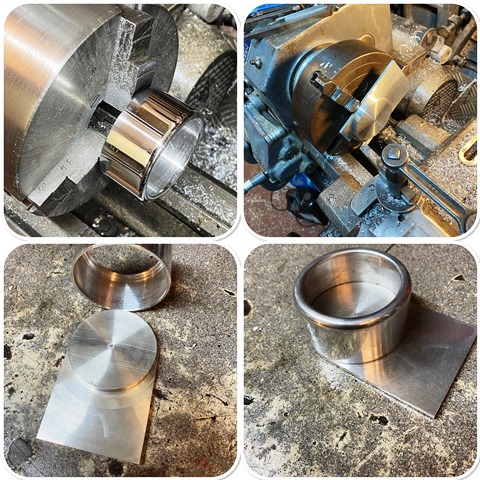

next up took some thought… I needed to hold the shaft while I undid the nut. It would have been Ideal to use an old UJ but I didn’t have one… But what I did have was an old drive shaft. Out of this I made a stepped broach in the the lathe and then hardened it. With this I was able to broach a set of splines in a block of 10mm alloy, cut to fit a large spanner. It worked a treat!

finally, I made a tool to remove the castellated nut on the input shaft from an old socket, and a tool to hold the clutch hub from an old clutch plate. I think that may be it as far as special tools go!

I have been debating replacing my milling machine for a long time… but I have had it for almost 45 years and its like an old friend! over the years it done a lot of work, but its a 1929 machine and has its limitations! When my wife asked me what I wanted for my Birthday it was an easy answer! The old machine has gone to a good home where I know it will be looked after and used…