Rebuilding rear fender, everything starts with Cardboard Aided Design software:

I'm raising that area that tire hit, as well as eliminating lower plastic piece. I'll have my fender run down in front of swing arm to prevent dirt from rear wheel going to clutch lever area:

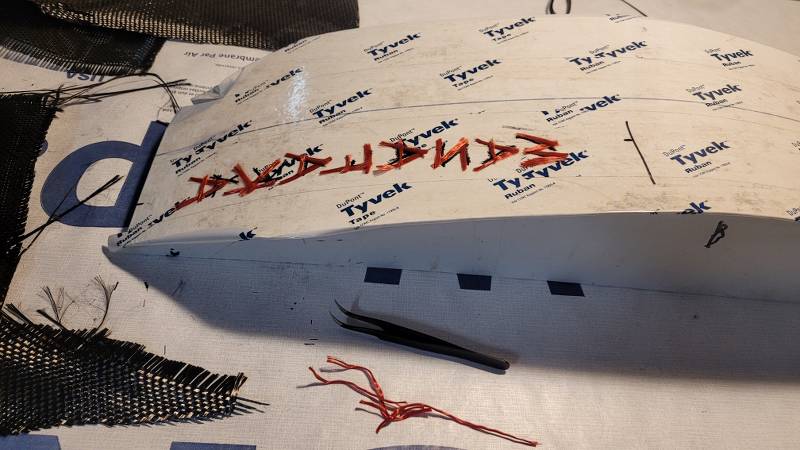

I could start with a flat piece of carbon/fiberglass sheet, it would bend that much, but since I want it to extend in front of swing arm, I have to form it in it's shape because flat sheet will want to spring back to being flat and be rubbing to clutch lever area. So made curved mold using FPR construction fiberglass sheet where I'll form carbon/fiberglass sheet:

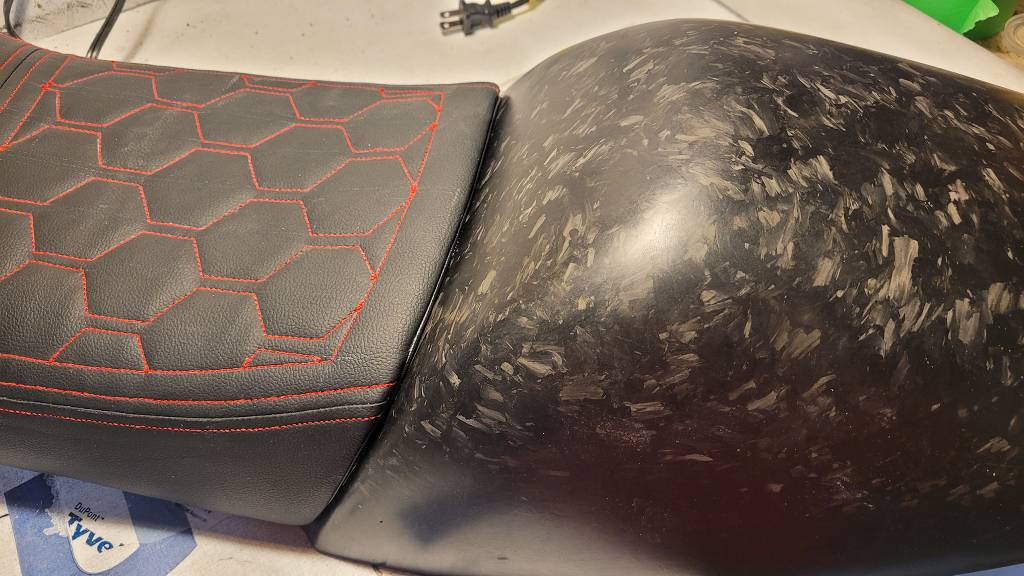

And back to my headlight bucket, mold shaping is done and it's been "carbonized". Yes, I just invented a new word... lol Once cured I'll cut it to shape I want and then skin it with forged carbon fiber.

I'm raising that area that tire hit, as well as eliminating lower plastic piece. I'll have my fender run down in front of swing arm to prevent dirt from rear wheel going to clutch lever area:

I could start with a flat piece of carbon/fiberglass sheet, it would bend that much, but since I want it to extend in front of swing arm, I have to form it in it's shape because flat sheet will want to spring back to being flat and be rubbing to clutch lever area. So made curved mold using FPR construction fiberglass sheet where I'll form carbon/fiberglass sheet:

And back to my headlight bucket, mold shaping is done and it's been "carbonized". Yes, I just invented a new word... lol Once cured I'll cut it to shape I want and then skin it with forged carbon fiber.