07JGM

Tuned and Synch'ed

Hi all,

Thank you for your great support on this topic.

This is where I'm at:

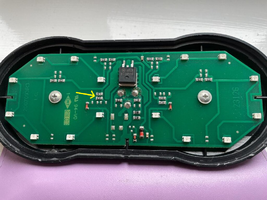

- did some initial electronic measurements on the PCB, and one of the earlier dead LED's fired up; made me thinking that the LED's themselves are not the issue;

- the PCB is organised such that left and right LED's are mirrored in terms of their electric feed;

- the 8 (per side) LED's are fed in 2 strings of 3 LED's and 1 string of 2 LED's;

- the string of 2 LED's is the problem area;

Currently working my way through some fault analyses on the circuit with a more knowledgeable friend.

I'll keep you posted on the progress and share the electronic schema once done.

I've attached a picture of the PCB and the PCB functioning in "brake-mode".

Jan

Thank you for your great support on this topic.

This is where I'm at:

- did some initial electronic measurements on the PCB, and one of the earlier dead LED's fired up; made me thinking that the LED's themselves are not the issue;

- the PCB is organised such that left and right LED's are mirrored in terms of their electric feed;

- the 8 (per side) LED's are fed in 2 strings of 3 LED's and 1 string of 2 LED's;

- the string of 2 LED's is the problem area;

Currently working my way through some fault analyses on the circuit with a more knowledgeable friend.

I'll keep you posted on the progress and share the electronic schema once done.

I've attached a picture of the PCB and the PCB functioning in "brake-mode".

Jan