Ok KayJay,

I have done a lot of thinking about your problem because you have been buggered up here badly.

You have given me much more information to work with. Let’s get this sorted out!

Bike was working then one morning, error and Service Triangle.

Let’s assume based upon this info, that it actually is a physical problem as opposed to a GuzziDiag screwed up situation.

Fastest elimination possible:

The Stepper Motor has 4 ECU pins going to in.

Uncover the ECU which if your small tank 2010 is like my 2012, it’s under the front tank side panel on the left.

Disconnect the battery cables completely from the battery, and clip the + & - cables together with a clamp or rubber bands or vice grips. Whatever is handy. Go have a coffee or two and leave this for 1 hour. This will drain the residual charge in the electronics and reset everything to a fresh new “ground state”.

AFTER 1 HOUR, SEPARATE THE + & - cables from each other and make sure neither is touching the frame anywhere before proceeding.

Now look at the wiring diagram. #40, the IDLE MOTOR. This is what we will test with the voltmeter. You speak technical so I will as well.

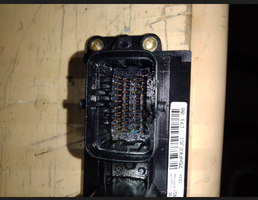

Go to the ECU cable and disconnect it from the ECU.

Locate the end pins on the cables. You are looking for the cable with the RED wire on pin 3. Pins 1 & 2 are empty with no wire attached.

Find pins 17, 18, 19, 20. They are respectively, SKY BLUE, YELLOW, PURPLE, GREY.

With your volt meter set to CONTINUITY, select 2 points on the engine or frame or one of each, and VERIFY ground CONTINUITY between those two points. This establishes your ground testing location.

Now, read each ECU pin one at a time to this established good ground point you previously identified in the last step.

NONE of the pins should have CONTINUITY to this ground point. If one does, then it is because the wiring loom has been pinched and or abraded to make contact with the frame or chassis somewhere along it’s length from the ECU end to the Stepper Motor end.

However, I suspect that you will have none of those 4 wires with CONTINUITY to ground. I think the error is caused by something different.

If I am correct, put everything back together and get ready to run the engine again.

If I’m wrong, you need to remove the tank and look for where the wiring loom has been abraded between the ECU and the Stepper Motor.

Instead, I think you may have induced a chemical continuity in the Stepper Motor and it’s housing itself by squirting lubricant into it or you may have shorted the windings.

You need a can of good old fashioned GUMOUT carburetor cleaner with all the nasty chemicals in it.

DO NOT BUY THE NEWFANGLED GARBAGE THAT IS ENVIRONMENTALLY FRIENDLY!

You need to spray some good 5 second bursts into the inlet like you did before, and get all of that lubricant out of there.

The Stepper requires no lubrication and should be clean and dry in order to function properly.

Some gentle blowing of compressed air into the inlet will assist with this.

See if this works before contemplating sending her someplace for diagnosis and repair.

The important part is finding out about those 4 wires and if one actually has continuity to ground or not.

Please post your results here.