I took some pictures while working on disabling the evap can yesterday. Hopefully this will help someone out there... :

Illustrated Procedure:

- remove seat

- remove left side panel (three bolts)

- remove starter cover (two bolts)

- locate vacuum tap line from manifold to canister under the gearbox

View attachment 13677

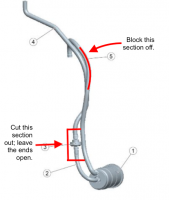

- cut vacuum line and block it (I glued an aluminum slug in place)

Follow the line and cut it in a convenient place, then block it ... particularly the upstream side that comes from the inlet manifold.

View attachment 13678

- locate breather line with valve connected to canister

- cut breather line above the valve and below at the canister inlet

View attachment 13679

View attachment 13680

- leave the breather line open ended behind the starter ... put a filter on it if you worry about environmental dust getting into the tank (but it ain't going to happen...

- replace starter cover

- replace side cover

- replace seat

Hope that's clear ... ask if you have any questions.